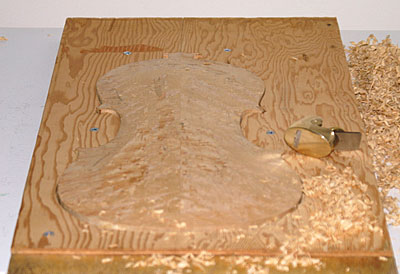

Carving the back

It started out as a beautiful 5/8" thick piece of Birds Eye Maple.

I would like to thank Rod Harder for helping true the plates before carving.

Using gouge chisels and thumb planes I worked to create the correct profile I wanted.

Here shows how I made some contour templates out of wood, copied from the Schroepfer back .

Checking periodically allowed me to get the correct contours as I carved.

Once I had the back contours it was time to hollow it out.

I set up a simple depth gauge for the drill press, set the stop at 5mm, and started drilling holes.

Notice it drilled the holes deeper toward the center and almost nothing at the outer edges.

Clamping the back down I proceeded to use a mallet and a gouge chisel to rough it out.

Then using three different sized thumb planes, I took it down to 5mm thickness by carving down to the bottom of the holes.

Setting up the drill press again, now to the precise depths in the different areas, I drilled more holes.

The plate thicknesses where of the Stradivari design, taken from Simone F. Sacconi "The Secrets of Stradivari" book This has a thicker oval shaped area in the middle of the "C" bouts of 4.5mm, tapering to 3.5mm towards the upper and lower bouts and edges of the "C" bout. A 2.5mm thickness in the upper area of the upper bout as seen in the photo above, and a 2.6mm thickness in the lower area of the lower bout.

When getting very close to the proper thicknesses, I would hold the the back by the upper left corner between my thumb and fore finger, lightly tapping the middle of the plate with my knuckle. Listening to the tone of the plate, I would take more wood out to raise the tap tone to the desirable frequency of the back plate. The desired frequency should be 1 1/2 semitone higher than the belly. E for the belly and F# for the back.

Back and ribs.

Below is after the back was sanded, starting with 320gt, finishing with 12,000gt.

Notice the difference with the photos above.

The wood shines like it was varnished.